Confronted with many challenges and barriers that put immense pressure on many British firms’ bottom line, it’s becoming more difficult for UK businesses to remain competitive in global markets. We’ve looked closely at the top three challenges facing Alpha Manufacturing, part of The HEX Group, and how we’re combatting these.

Increased Energy Costs – Due to an attempt to rapidly transition to renewable energy from fossil fuels, and the ongoing world conflict, energy costs are snowballing. Almost 60 per cent of companies within the manufacturing sector highlight how rising energy bills are threatening their business. Tackling this problem head-on, in 2022, Alpha Manufacturing installed 1770 solar panels covering 3,570.5m2 of roof space. Over 12 months, this will save the company 150t in CO2e carbon emissions and take the business one step closer to achieving carbon neutrality by 2037.

Recruitment Challenges, Staff Retention and Skill Shortage – The typical cost to recruit a new employee in the UK is £3,000. As a result of economic inactivity – people not working and not looking for work – labour supply and employment are below pre-pandemic levels. The need for skilled workers continues, but an ageing population and fewer young people taking vocational courses have compounded the problem, especially in the manufacturing and engineering sectors, which rely heavily on the expertise of engineers. Employing almost 500 employees across The HEX Group, Group People and Culture Manager Karen Barnacle faces these challenges regularly says

“Recruitment and retention have become a real challenge over the past 2 years, with vacancies that we would previously fill relatively easily now taking a lot longer. In order to try and alleviate this problem, we have implemented several recognition and reward packages for our employees including a 10% pay increase, a refer a friend scheme and an employee health cash plan. However, the lack of available skilled resource is still a real concern for us as a business”.

Supply Difficulties – Supply chain disruption in the UK can be very complex. High transport costs, Brexit trade barriers, global supply problems and panic buying have all contributed to manufacturing delays. Supply chain issues hinder economic development by preventing British companies from exporting goods abroad at competitive prices. Alpha Manufacturing has seen first-hand how the supply chain can affect day-to-day business.

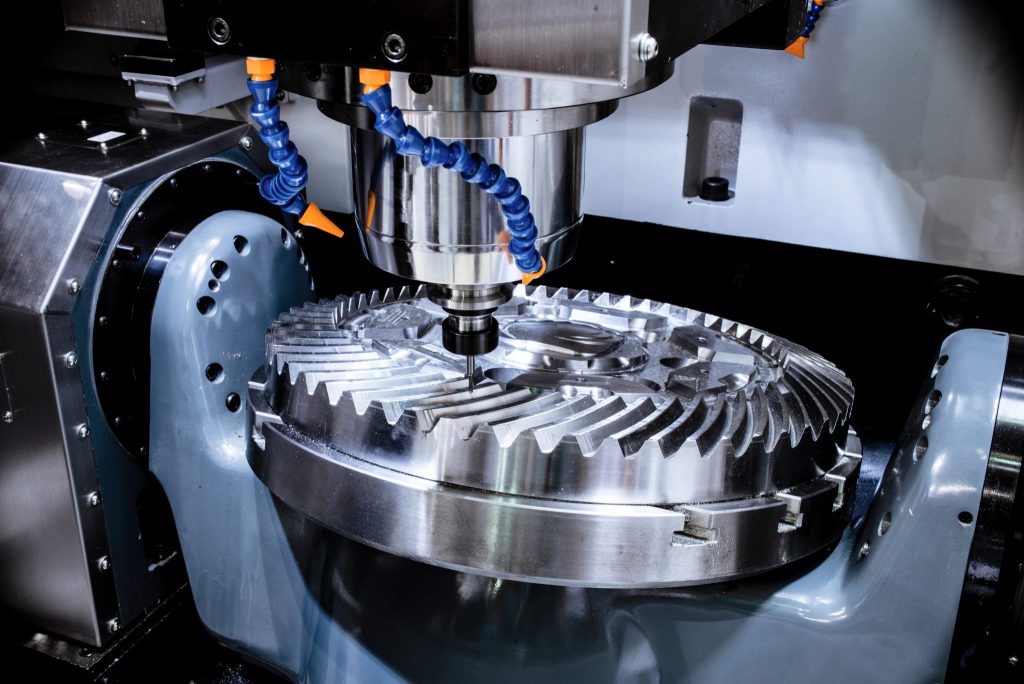

Michael Whitfield, Sales Director for Alpha Manufacturing, explains, “We’re passionate about investing in supply chain integration at Alpha. In the past, we’ve experienced challenges outsourcing certain processes to outside suppliers. By bringing more and more processes in-house and investing in capacity and automation, we take supply chain risk away from our customers and maximise production control. Similarly, since the pandemic, we have seen a surge in UK businesses looking to bring their supply chain back to the UK from overseas. As a British manufacturing business, we are happy to help our customers eliminate their challenges around delivery delays and import complexity”.

UK manufacturers are resilient by nature; however, they face another 12 months of uncertainty and remain stretched. At Alpha Manufacturing, we work closely with our customers to ensure we meet their project deadlines and deliver excellent quality products every time.