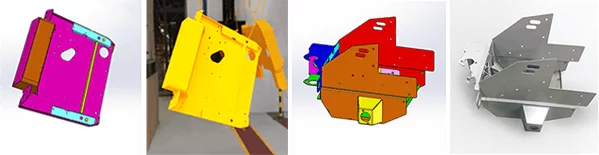

From project inception, our proficient in-house design team collaborates closely with customers to ensure seamless assembly processes and successful prototypes. To uphold specifications and quality, we have dedicated New Product Introduction (NPI) staff overseeing the manufacturing of metal parts, meeting our customers’ expectations.

Our experienced team continuously optimizes new developments, leveraging cutting-edge machine and tooling technology. This approach guarantees maximum efficiency while upholding the highest standards of quality for our valued customers.