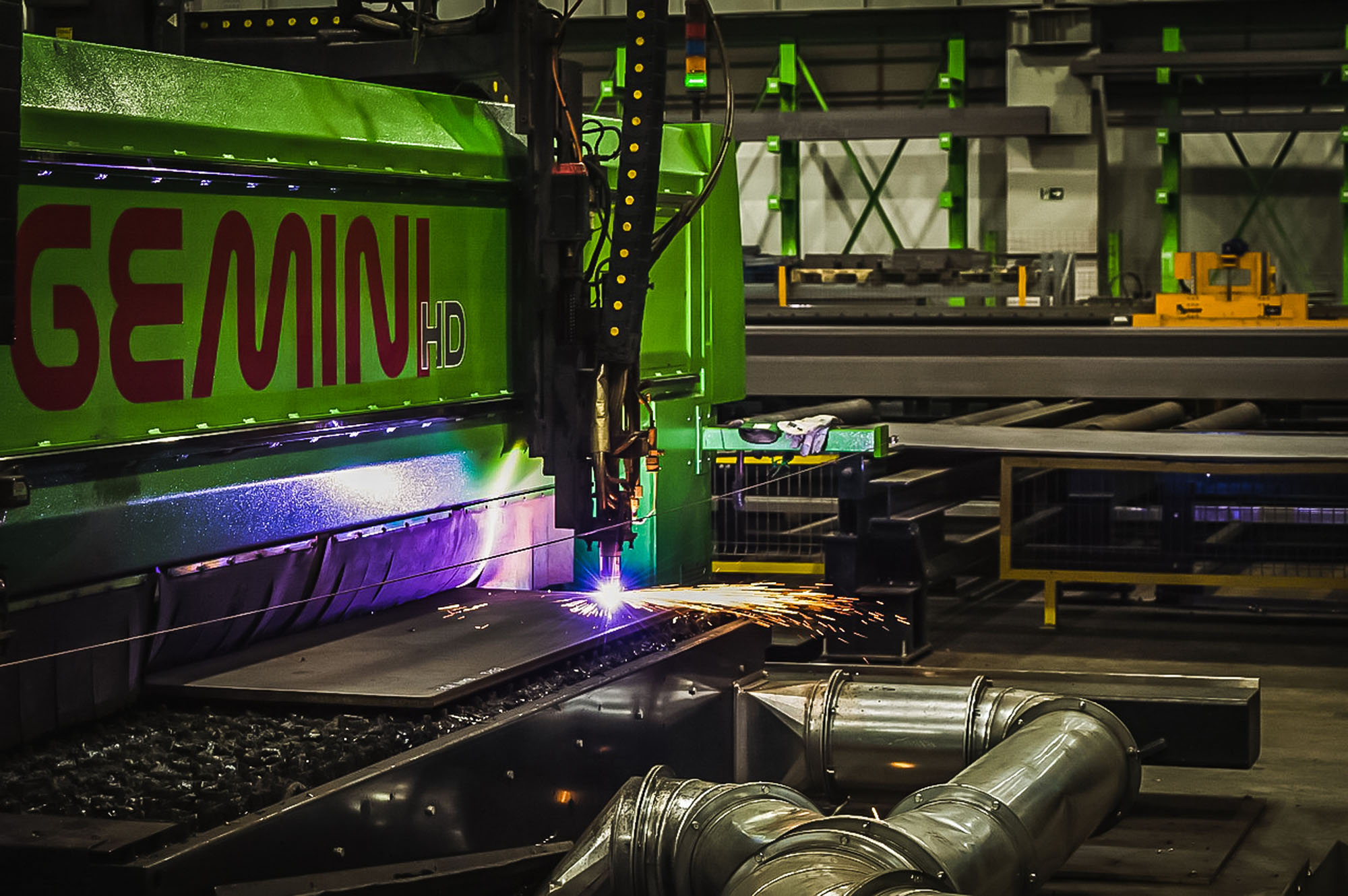

Often, a similar outcome can be achieved by punching sheet metal and laser cutting and so we often take into account certain factors before choosing one of the other, for example:

- Our preference at Alpha Manufacturing is to use a laser cutting machine over a punch machine for any material over 3mm. Although our machines can punch this thickness, the life of a punch tool can be significantly extended by limiting the material thickness in this way.

- Waste is always an important consideration when choosing between the two methods and generally, the laser machine will produce less waste than a punch machine. The “clearance” (space required between shapes) in a punch nest is much more than that of a laser, meaning that there will usually be more material wasted per sheet.

If you have a question regarding CNC punching or any other sheet metal processes, please get in touch